Products

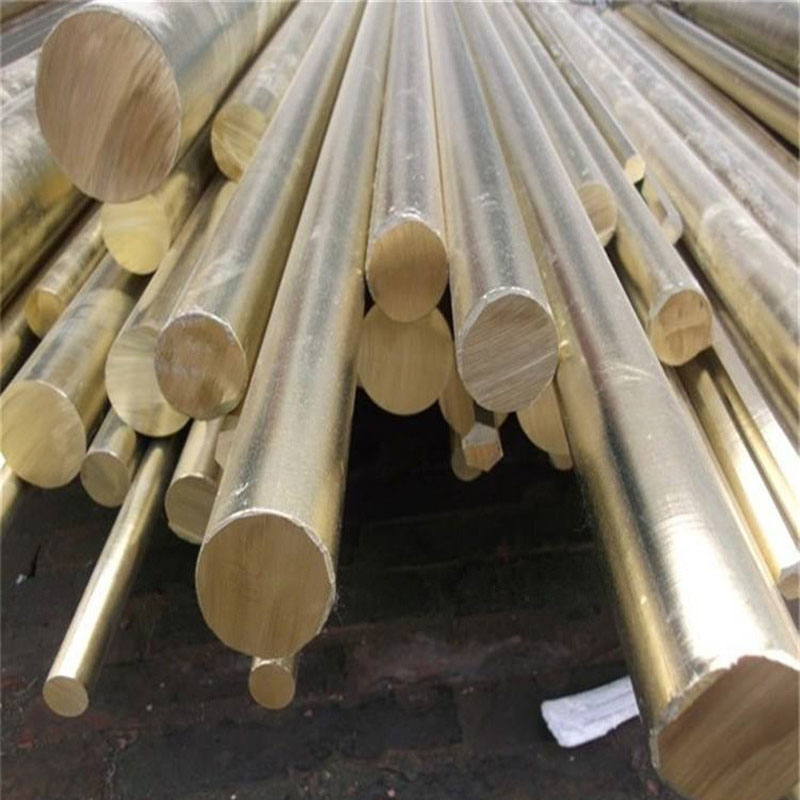

Brass row

Five Advantages Of Products

- High strength

- Good plasticity

- Good machinability

- Good mechanical properties

- Suitable for cold and hot working weldability

Product Details

mechanical property:

Tensile strength: ≥ 315

Elongation: ≥ 30

Heat treatment specification:

Hot working temperature 650 ~ 850 ℃

Annealing temperature 600 ~ 700 ℃

The low temperature annealing temperature for eliminating internal stress is 270 ~ 300 ℃

Type:

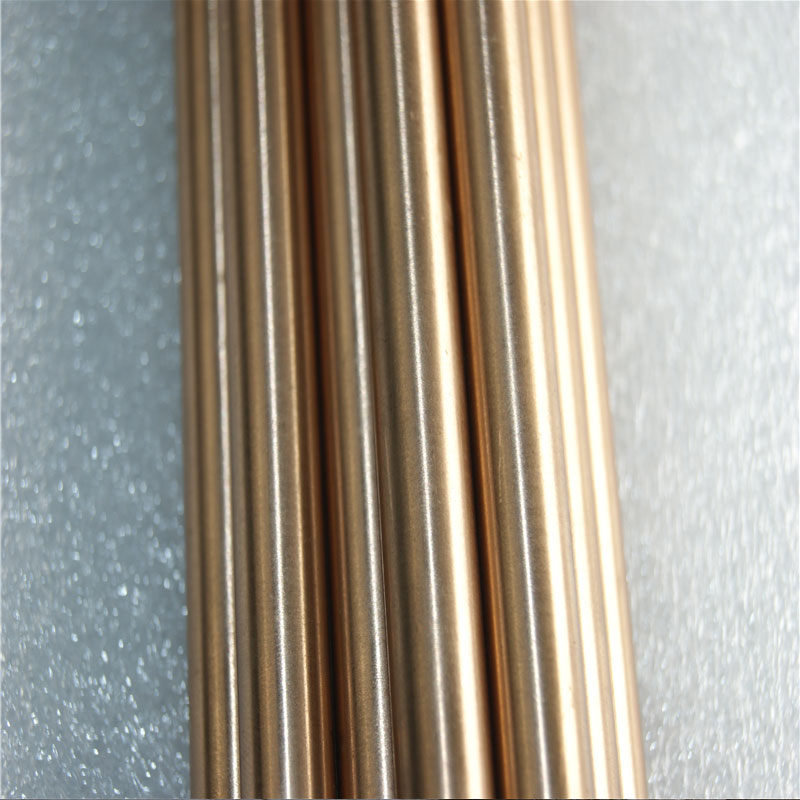

H59 brass consists of 59% copper and 41% zinc

H62 brass consists of 62% copper and 38% zinc

Main features:

Brass row has high strength, good plasticity, suitable for cold and hot processing, good weldability and corrosion resistance, good mechanical properties, good plasticity in hot state, good machinability, good weldability and corrosion resistance. The composition of copper and zinc is called ordinary brass, and the composition of more than two elements is called special brass, Its performance is also different. At the same time, brass row can be made into different specifications according to its actual needs.

Purpose:

Brass row is used for terrazzo copper bar, decorative copper bar, antiskid, metal stamping and carving

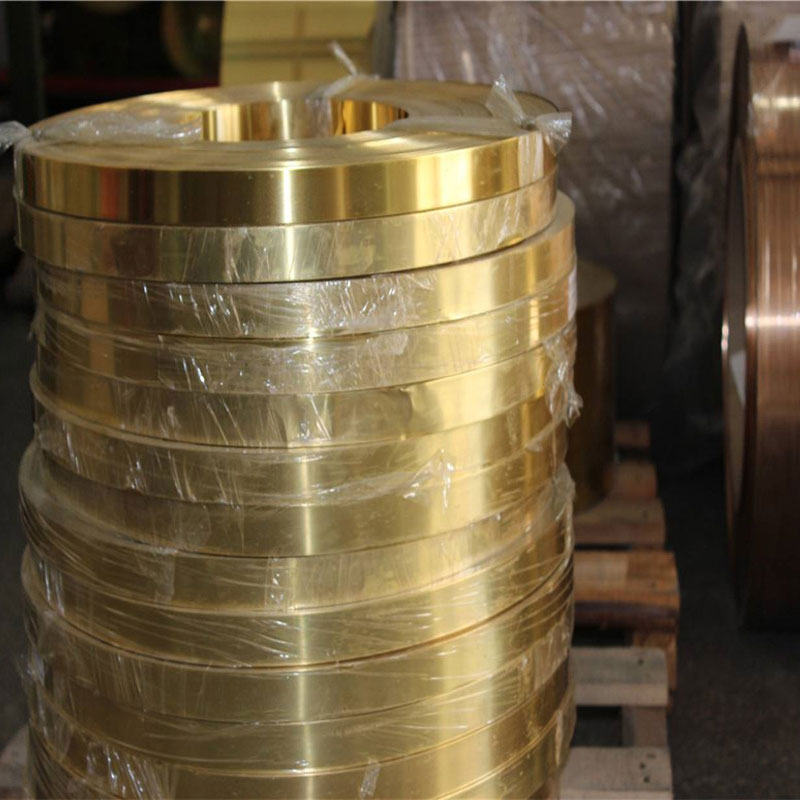

Specification:

Thickness 2mm-20mm

Width 5mm-120mm

Dongguan Nongda Metal Material Co., Ltd.

Contact Person: Juddy Zhang

Department: Business Unit

Post: business manager

Telephone: +086 13925896355

Landline: +086 0769-85303332

Company Address: Shunchang Industrial Park, Second Industrial Zone, Xiaobian, Chang'an Town, Dongguan City, Guangdong Province

Website: nongdametal.us764.com

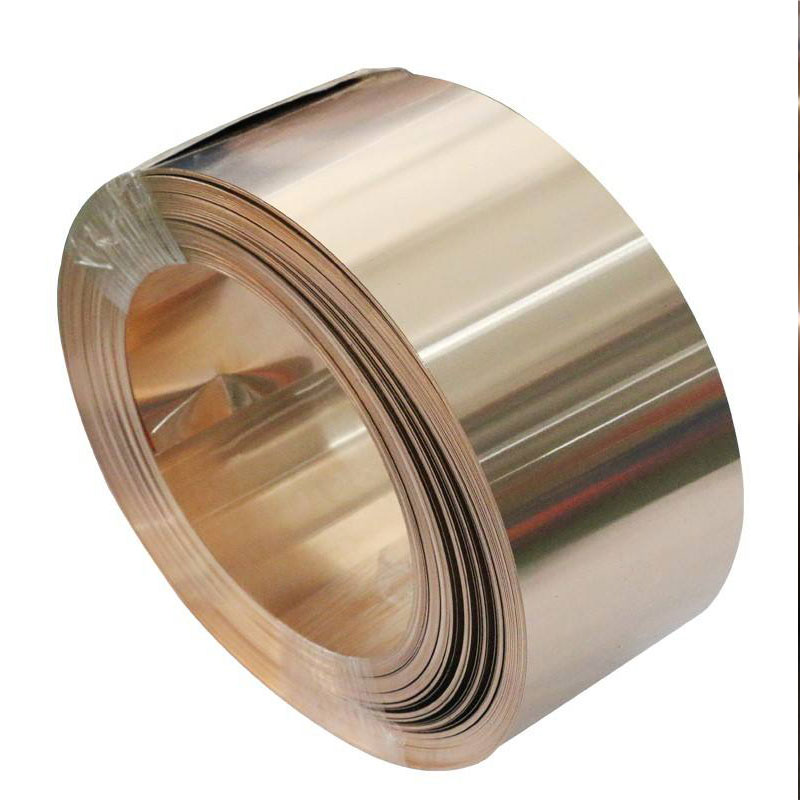

Previous: Brass strip

Next: Copper phosphate rod